Since my last write up in January 2020, my 13 flasks have been mostly growing very well. Biofilms have been forming and have been shaken off and then new biofilms forming. I have taken regular photos to track progress, though due to Covid lock downs my visits to the lab and work with the flasks has been less regular than I wished.

I was delighted to find that the cultures survived this lack of attention. It occurred to me that not only was the process of shaking off of biofilms important to the process but also everytime it was done it allowed a change of air around the filter cap flasks and that could be important too. I don't know how quickly the air is depleted in the box holding pretty tightly packed in flasks, but the sense of a vaccum when opening the box made me think that the air had been depleted somewhat.

Over the last few months it has been clear that the biofilms were growing more slowly and starting to disappear, so the big question was, had tuberculomucin (Tbm) developed?

The test fot Tbm is a couple of drops of 20% acetic acid. In previous tests of some old cultures which had been left in an incubator without attention we found that there was a reaction of cloudiness/white bits whereas just growing medium had no visible reaction. However Friedrich had clearly stated that the cloudiness reaction was not what we were looking for and likely indicated the presence of albumins and was not therapeutic and should be disposed of. What we were looking for was a coherent clumping after shaking.

At the beginning of December we were at last able to do the acetic acid test on the growing medium in the flasks. Imagine my excitment when we got a clear clumping reaction in those flasks which had been regularly shaken and not in those which either hadn't grown well or hadn't been shaken!

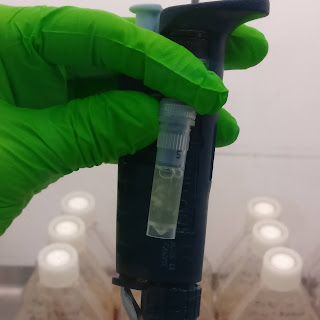

Take a look at the shape in the liquid. This is a few minutes after adding 2 drops of acetic acid. The vial has not been shaken.This vial has been shaken and the form is more definitive11 days later we took photos again

Vial W3 is Weleminsky broth with H37rv strain of TB - this grew well, though took a longer time than in Oxoid nutrient broth to get going, and has been regularly shaken. Lots of clumping - hopefully this is Tbm. W4 has a clinical TB strain which never grew very well and has not been shaken. No indication of Tbm.

So I'm pretty excited. I really think we have Tbm!

Judy Weleminsky